Engineering the foundation of automation.

Our “Think” services define how ideas become machines — combining precision design with scalable architecture.

Feasibility Studies & R&D – Validating emerging automation concepts and new manufacturing technologies.

Mechanical Design – Precision design for industrial automation systems, robotics, and production equipment.

Software Architecture – Reliable, modular software for machine control and production integration.

System Architecture – Unified mechanical, electrical, and digital systems engineered for seamless automation.

Transforming concepts into working machines.

In this phase, we turn designs into functional, production-ready systems that can scale with your business.

Rapid Prototyping – From functional 3D-printed models to complete test machines.

Production-Ready Machines – Design and build of industrial-grade automation systems.

Electronics & Control Systems – Custom PCBs, sensors, and firmware for intelligent motion control.

Automation Integration – Robotics, conveyors, and data systems built to communicate and perform autonomously.

Accelerating your technology into production.

We help you take your product or system to the world — efficiently, intelligently, and sustainably.

Component & Machine Production – From small-batch parts to full production lines.

Maintenance & Lifecycle Support – Long-term optimization and reliability assurance.

Data & Performance Optimization – Using real-time analytics to improve system performance and uptime.

From design to deployment, Motion Dynamics moves ideas into action.

Featured Project:

Custom 3D Printer for Orthotic Insoles. We engineered a complete solution for Insolution, an orthopedic manufacturing company.

Mechanical Design:

High-precision motion systems for flexible materials.

Electronics & Firmware:

Custom control hardware for reliable performance.

Software Integration:

Full CAD-to-print workflow for seamless production.

Deployment:

End-to-end manufacturing setup and production scaling.

This custom 3D printing system transformed traditional orthotic manufacturing into an automated digital process, improving speed, consistency, and scalability.

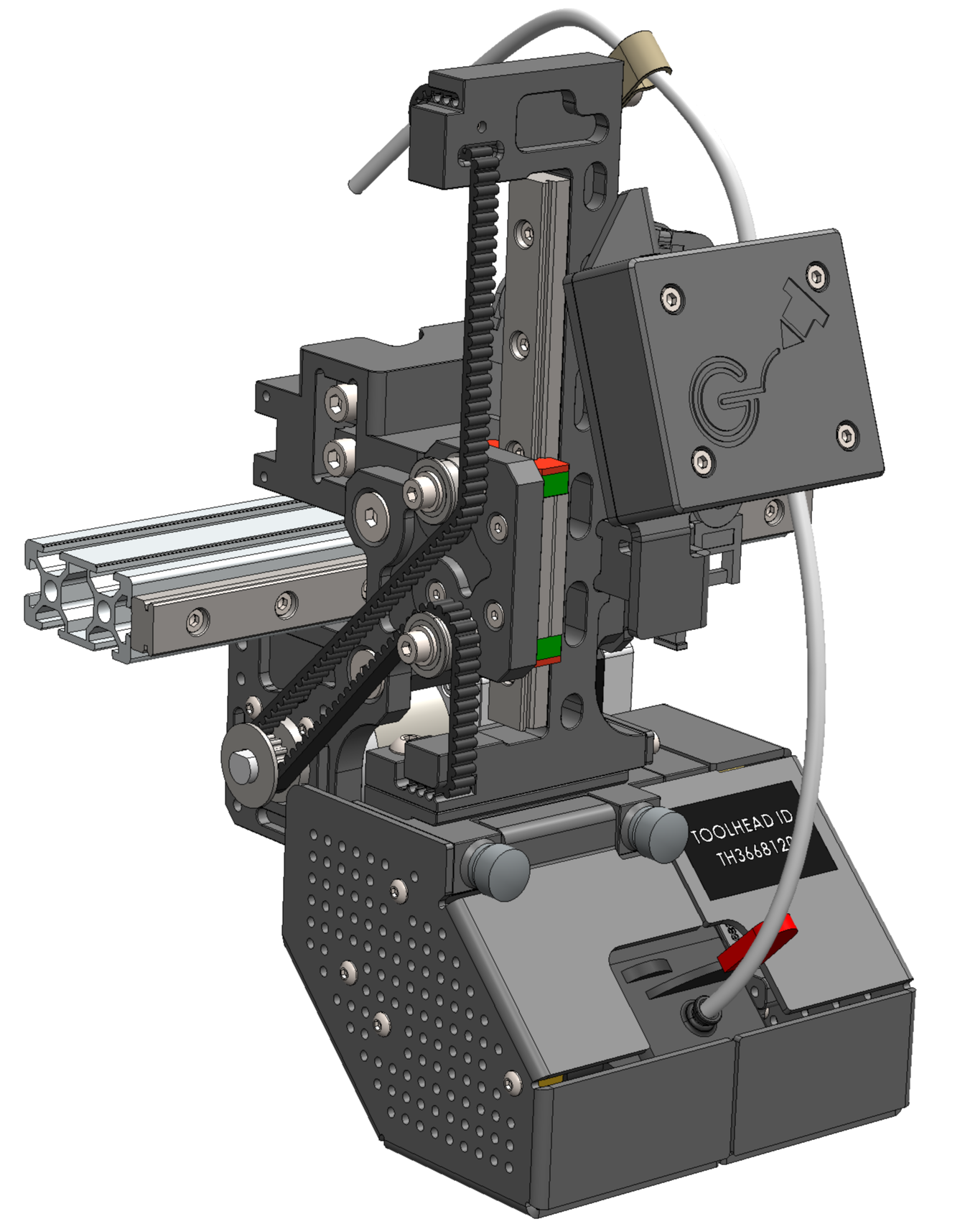

Custom Toolhead

This modular toolhead is purpose-built for 3D printing medical insoles, integrating all wear-prone and critical components into a single, easily swappable unit.

It enables end-users to quickly replace or upgrade the printhead, reducing downtime and ensuring consistent print quality.

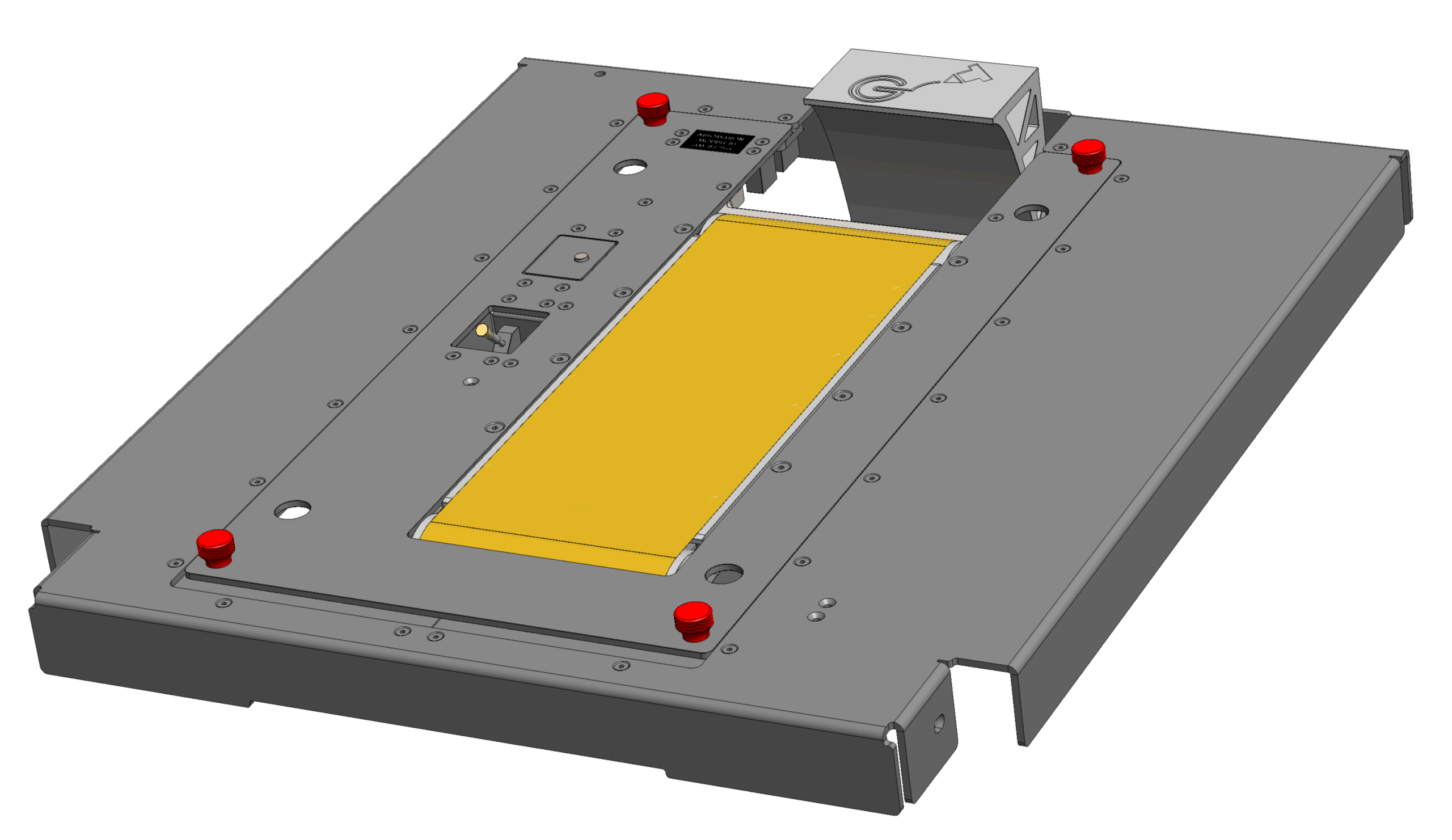

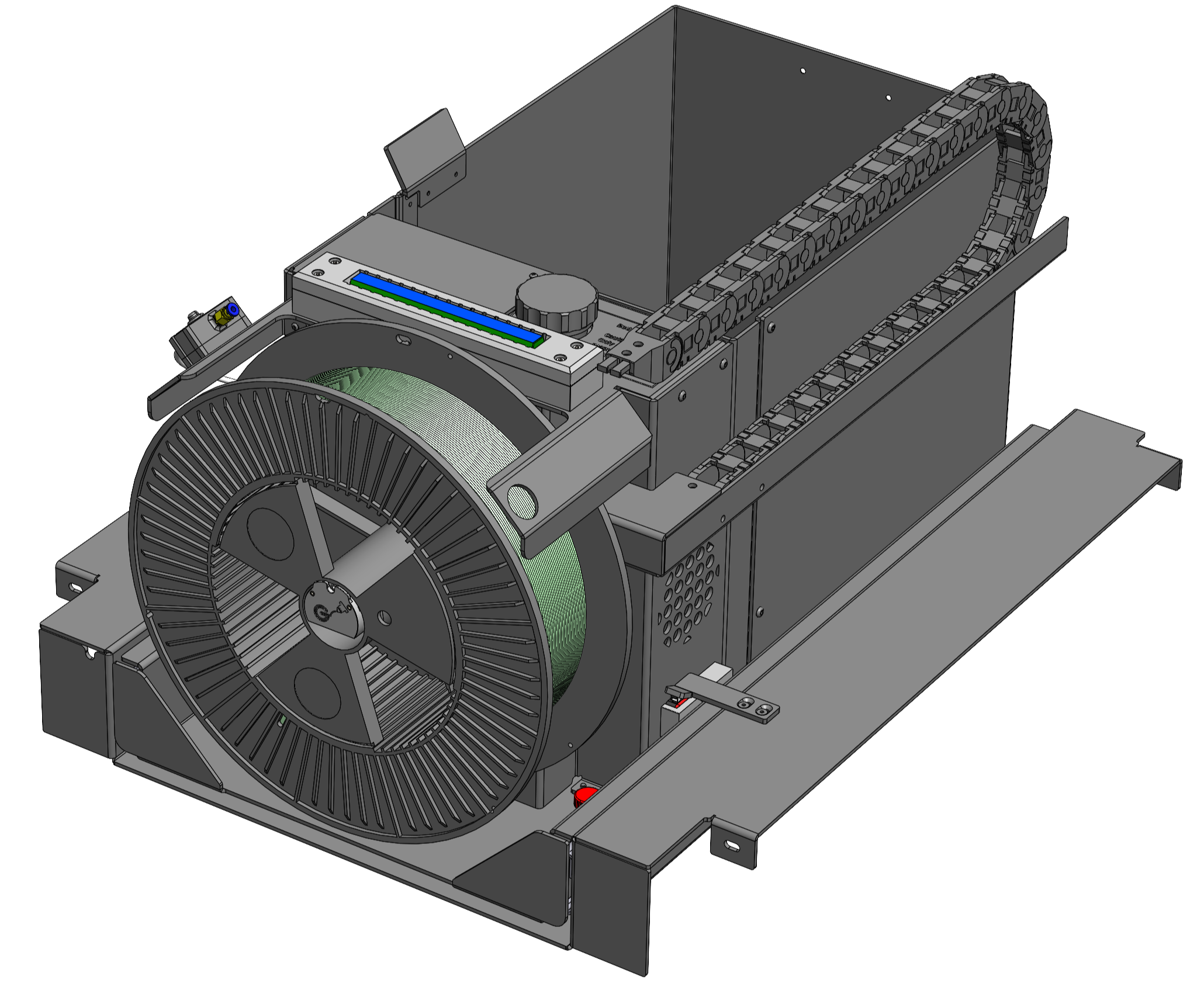

Continuous Printing Module

This module enables uninterrupted 3D printing by using a heated conveyor belt with an adhesion-optimized surface, ensuring reliable part bonding and automatic part release.

Its modular design allows easy swapping for maintenance or production changes, minimizing downtime and maximizing efficiency.

Collector and Filament Module

The CFM (Collector and Filament Module) automates material management and post-print handling by monitoring filament use, collecting finished insoles, and cleaning the Continuous Printing Module after each print cycle.

It streamlines production and ensures consistent, maintenance-free operation.

Engineering the Future of Intelligent Manufacturing.

Motion Dynamics is a Dutch engineering company specializing in machine design, industrial automation, and production system development.

Our multidisciplinary team — mechanical, electronic, and software engineers — works together to build machines that think, move, and evolve.

We believe in the vision of the dark factory:

a production ecosystem where automation runs autonomously, safely, and efficiently — freeing human creativity to focus on innovation.

Our mission is to help companies embrace automation and achieve smart manufacturing excellence through advanced engineering and seamless integration.

Nikkelweg 55

2401MM Alphen aan den Rijn

The Netherlands

Call and WhatsApp

+31 (0)85 029 30 13

info@motiondynamics.nl

VAT No.: NL866200666B01

CoC No.: 92873022

Motion Dynamics B.V.

Scan to add us to your contacts!